Basic Info.

Product Description

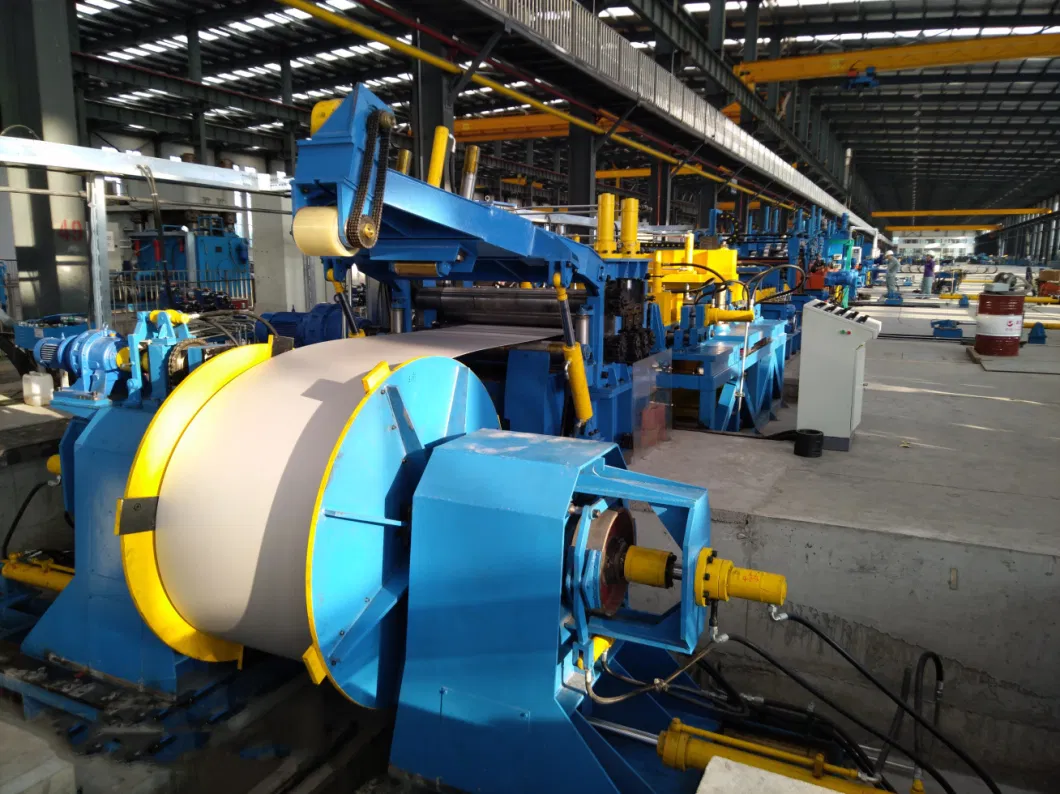

Stainless Steel Pipe Making Machine Tube Production Line

The plate in certain width after slitting line and stripping is unfolded and leveled. Then, they are sent into forming machine. Used the roller, the plate is bent into pipe state. The pipe is welded by plasma welder and Tig welder.

Large stainless steel welded pipe mill adopts automatic flexible forming technology.

In recent year, our company developed the precise control forming. The advantage of this kind forming is to guarantee the excellent forming quality in rough forming section through the precise control. Then it is no need to have the repair management in precise forming section. Therefore, the precise forming in this forming method does not need to change the roller. All the forming section does not need to change the roller, which solves the problem of the change in precise forming section and non-change in rough forming section. Therefore, it saves the roller investment and decreases the time of roller changing. Besides, during the diameter changing, all are controlled by industrial computer. The roller will automatically reach the position by inputting the pipe diameter, pipe wall thickness, material and other parameters. It largely improves the mill efficiency and pipe qualified rate. This forming method is suitable for medium and large mill from 219mm to 711mm, which saves the investment and improves the efficiency.

Large stainless steel welded pipe mill is mainly used for manufacturing the industrial pipe in chemical, the bottom sea, oil, gas delivering and other field. The pipe requirement on the material and quality is very strict. The machine has internal welding seam leveling treatment, solution annealing, X-ray detector, UT detector, high pressure hydrotester, and other equipment.

Model:

| No. | Model | OD (mm) | Speed (m/min) | Thickness (mm) | Installed Capacity (kw) | Area (M2) |

| 1 | HNBXG-219 | Φ89 - Φ219 | 0.1 - 1.8 | 2.0 - 10 | 100 | 24×200 |

| 2 | HNBXG-273 | Φ89 - Φ273 | 0.1 - 1.8 | 2.0 - 10 | 120 | 24×200 |

| 3 | HNBXG-325 | Φ140 - Φ325 | 0.1 - 1.5 | 2.0 - 12 | 250 | 24×200 |

| 4 | HNBXG-355 | Φ140 - Φ355 | 0.1 - 1.5 | 2.0 - 12 | 250 | 24×200 |

| 5 | HNBXG-406 | Φ165 - Φ406 | 0.1 - 1.5 | 2.0 - 12 | 250 | 24×200 |

| 6 | HNBXG-426 | Φ165 - Φ426 | 0.1 - 1.5 | 2.0 - 14 | 300 | 24×300 |

| 7 | HNBXG-508 | Φ219 - Φ508 | 0.1 - 1.5 | 3.0 - 14 | 350 | 30×300 |

| 8 | HNBXG-610 | Φ273 - Φ610 | 0.1 - 1.5 | 3.0 - 14 | 350 | 30×300 |

| 9 | HNBXG-630 | Φ273 - Φ630 | 0.1 - 1.5 | 3.0 - 14 | 400 | 30×300 |

| 10 | HNBXG-660 | Φ273 - Φ660 | 0.1 - 1.5 | 3.0 - 14 | 400 | 30×300 |

| 11 | HNBXG-711 | Φ325 - Φ711 | 0.1 - 1.5 | 3.0 - 14 | 400 | 30×400 |

Working Process:

Coil Loading - Uncoiler - Leveler - Steel Cutting and Welding - Small Accumulator - Forming - PPT Welding - Internal Welding Seam Leveling - Online Annealing - Water Cooling - Sizing - Cut to Length - X-Ray Detector - Pipe End Facing and Beveling - Hydrotester - Solution Treatment - Offline UT Welding Seam and Pipe Detector - Acid Pickling Passivating - Weighting, Measuring, Marking - Pipe Collection

Packing & Shipping

1. We use steel wire and wooden frame to fix the pipe mill.

2. In addition, used shockproof film to protect the main motors.

3. We use containers for shipping.

4. Generally speaking, we start at Tianjin sea port, but we also can start at other port according to customers need.

Our Customer

Integrated Services

1. Provide customers with a reasonable investment plan, filter the appropriate models recommended to customers.

2. Free equipment drawings, customer plant equipment planning drawings.

3. Provide the base map required for installation free of charge.

4. Provide equipment installation and commissioning until the buyer operates normally.

5. Provide professional technical training, as soon as possible to allow the buyer's operator to master the operation and use of the equipment.

6. Provide and coordinate auxiliary equipment, accessories, and consumables.

7. The warranty period is one year, except man-damage. If you have any question in operation in operating the machines, you can call us or send emails, we will solve the problem for you asap.