- Overview

- Product Description

- Product Parameters

- Detailed Photos

- Our Team

- Contact Us

Basic Info.

Packaging & Delivery

Product Description

Product Description

This production line is push-pull Acid Pickling Unit, which adopts the most advanced Shallow Trough Turbulence Acid Pickling technology. The equipment and technology provided are reliable advanced mature whole set equipments and technology that could fulfill the buyer's need of steady production and long-term running which are proved by actual production. This technology is featured by reasonable structure, high efficiency, low consumption, convenient operation, fewer malfunctions.

1.Push-pull pickling adopts advanced shallow turbuleimmernt pickling process, with short pickling time and high pickling efficiency. Push-pull pickling can be divided into six sections, each section has its own outer heating and pickling system, through adjusting the temperature of every pickling sections to achieve the best pickling effect.

2.Continuous pickling adopts turbulent shallow pickling process with extinct advantages. The liquid height inside the acid tank is just 150mm, the inner and outer cover of the acid tanks, all can reduce the evaporation and improve the turbulence speed of the acid liquid.

3.Continuous pickling line has three acid tanks, each of them has separated outer heating system and acid recycled system. Through adjusting the temperature, concentration and the turbulence speed of every acid tank to achieve the best acid effect.

4.Using five-stage counter follow cascade rinse system, only need few rinsing water. Though controlling the accuracy of the conductivity in the last rinsing section to ensure the rinse quality of the strip surface.

5.Continuous pickling line has set 800t rolled skin pass mill to improve the defects of the strip shape and the quality of the strip surface, as well as eliminate part of the yield platform, and improve the product competitiveness.

6. Continuous pickling adopt reliable technical, stable running double head rotate tower side trimmer, the open degree of the shear blade, overlap amount, side seam can be adjusted automatically.

During the hot rolling process, a layer of brittle and hard oxide is formed on the surface of the steel coil. Before the cold rolling process, the oxide on the surface of the coil must be removed. This process is usually completed by the pickling unit.The pickling unit is divided into push-pull pickling production line and continuous pickling production line.

During the hot rolling process, a layer of brittle and hard oxide is formed on the surface of the steel coil. Before the cold rolling process, the oxide on the surface of the coil must be removed. This process is usually completed by the pickling unit.The pickling unit is divided into push-pull pickling production line and continuous pickling production line. Product parameters

Design basis

| Raw Material | Cold rolled carbon structural steel, high quality carbon structural steel and low alloy steel coil |

| type of steel: | Q195, Q235 ,ST12 ,ST13, SPCC ,SPCD20#. |

| Hot belt temperature | ≤55 Centigrade |

| Yield strength: | 210~360N/mm2 |

| Tensile strength: | 270~610N/mm 2 |

Specification:

the thickness of steel: 2.0~~3.5mm

the width of the steel: 650~750mm

Inner diameter of coils to be pickled: Φ610mm/Φ760mm

Inner diameter of coils after being pickled: ф508mm

min Φ900mm

coil inner diameter: max Φ1800mm

min Φ900mm

coil unit weight max 13t

annual work plan: 300 days*24 hours

Energy: water, electricity and vapor

Product form: coils one after another

Production capacity: 200000tons/ Year

1. We are the leading manufacturer of metal coating machines in China, and we can give you the best price. We warmly welcome you to visit our factory at any time.

2. We have professional design engineers who can design and customize production lines according to your requirements.

3. Professional installation, good after-sales service and rich installation experience.

Product pictures for reference

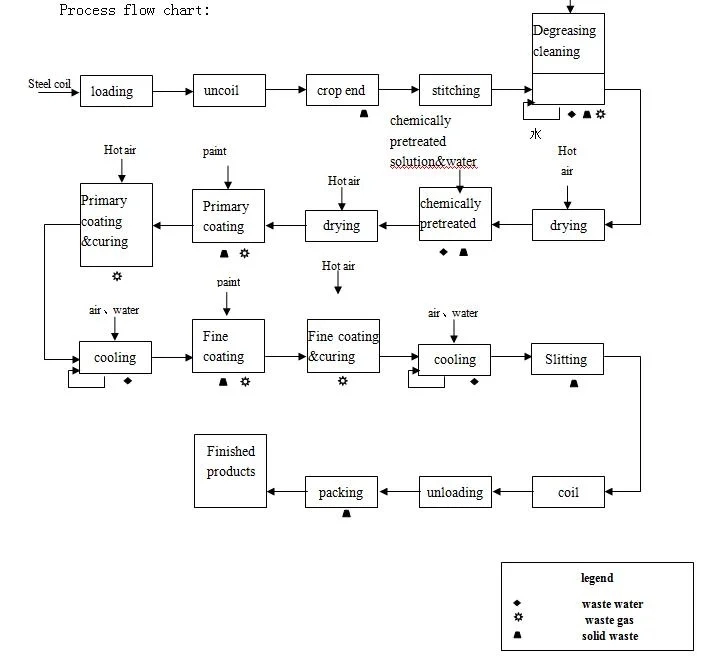

Simple process for the color coating line

Simple process for the color coating line

Our teamwork is serving you all the time

Send us an inquiry about the color coating line

FAQ

FAQ Q 1: Are you Manufacturer or Trading company?

A:We are a professional manufacturer with our own export department. So you can get best price from us.

Q 2: Where is your company located? How can I visit there?

A:Our company is located in Binzhou, near ZIBO train station. All clients, from home and abroad, are warmly welcomed to visit us.

Q 3: What is your terms of delivery?

A: Normally our quotation is under FOB Qingdao, but we also accept EXW, FOB(other seaports), CFR, CIF, DDU and so on.

Q 4: What is your terms of payment?

A: By T/T, 40% as deposit for production, and 60% balance before delivery. We'll show you the photos of the products and packages before you pay the balance. Other payment terms are as negotiated. For small amount order, we also accept WU, Paypal, MoneyGram and so on.

Q 5: What is your terms of packing?

A: Generally, we pack our goods by thicker bubble paper, some of them are packed by carton, and wooden box as required.

Q 6: How about your delivery time?

A: Generally, the goods will be ready within 7 to 10 days after receiving deposit for standard goods. Some kinds are even in stock. If your voltage is different from 380V/3PH/50Hz, the delivery time will be a little longer for custom-made motors or electric components.

Q 7: Can you produce according to the technical drawings?

A: Yes, we can produce by your technical drawings or requirements. We also can make drawings for you.

Q 8: How do you make our business long-term and good relationship?

A1. We keep good quality and competitive price to ensure our customers benefit;

A2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Q 9: How about the quality of the products?

A:With the advanced machines, strong and professional R&D team and material sources, our products are excellent in performance and craftsmanship.

Why Choose Us

1.More than 10-year manufacturing experience involved in this industry, and 10-year rich export experience

2.Superb unique technology and Automatic production line.

3.Large order can be placed.

4.Advanced equipment and exquisite workmanship.

5.Durable and reliable

6.Professional pre-sales and after-sales service