Basic Info.

Model NO.

pickling line

Process Method

Push-Pull Shallow Trough Turbulence Hydrochloric a

Apu Layout Direction

Left to Right When Seating at Operation out Board

Max. Process Speed

70-150m/Min

Process Speed in Changing Coil

50-60m/Min

Point Move Speed

10-30m/Min

Transmission Way

AC Driving System, Speed Regulated by Variation

Acid Concentration Max

200g/L HCl, 125g/L Fe2+, 5 G/L Fe3+

Fluorine Content in Acid

Less Than 4ppm

Minimum Pickling Time

26s

Acid Trough Length in Total: About

50m

Transport Package

Plastic Film/Plywood Box / as Clients′ Required

Specification

it depends on the specification

Trademark

Moran or customized

Origin

Hebei, China

HS Code

722100000

Production Capacity

5-10 Sets

Product Description

Brief Introduction about Shallow Turbulence Type of Pickling Line

Pickling line is used to clean out the surface of hot rolled steel strip. It also contains surface leveling, side trimming and rust prevent function.

During the last 13 years working in pickling process, Moran continues improve its technology on pickling rate, production efficiency, machine reliability and environmental protection.

Today Moran supplies shallow turbulence type pickling line with following type:

*Steel rube granite tanks + FRP cover

*Granite tanks and cover + steel frame

*PPH tank and cover + steel frame and granite inner

Technical Parameter:

Hebei Moran provides the customers with all-around, high value-added pre- sales & after-sales services. Factory design, selection of utility & auxiliary facilities, unit process layout, civil foundation design reference, as well as the well-rounded training combined with theory and hands-on exercises for line operators and maintainers, all are freely available.

Pickling line is used to clean out the surface of hot rolled steel strip. It also contains surface leveling, side trimming and rust prevent function.

During the last 13 years working in pickling process, Moran continues improve its technology on pickling rate, production efficiency, machine reliability and environmental protection.

Today Moran supplies shallow turbulence type pickling line with following type:

*Steel rube granite tanks + FRP cover

*Granite tanks and cover + steel frame

*PPH tank and cover + steel frame and granite inner

Technical Parameter:

| Input Material: | Hot rolled Coil |

| Coil Thickness Range: | 1.5-6.0mm |

| Max. Coil Width: | 1550 mm |

| Max. Line Speed: | 150 m/min |

| Pickling Medium: | HCL |

| Max. Coil Weight: | 30 T |

| Max. Anneal Capacity: | 500,000 T/Y |

Hebei Moran provides the customers with all-around, high value-added pre- sales & after-sales services. Factory design, selection of utility & auxiliary facilities, unit process layout, civil foundation design reference, as well as the well-rounded training combined with theory and hands-on exercises for line operators and maintainers, all are freely available.

You are warmly welcomed to visit our workshop.

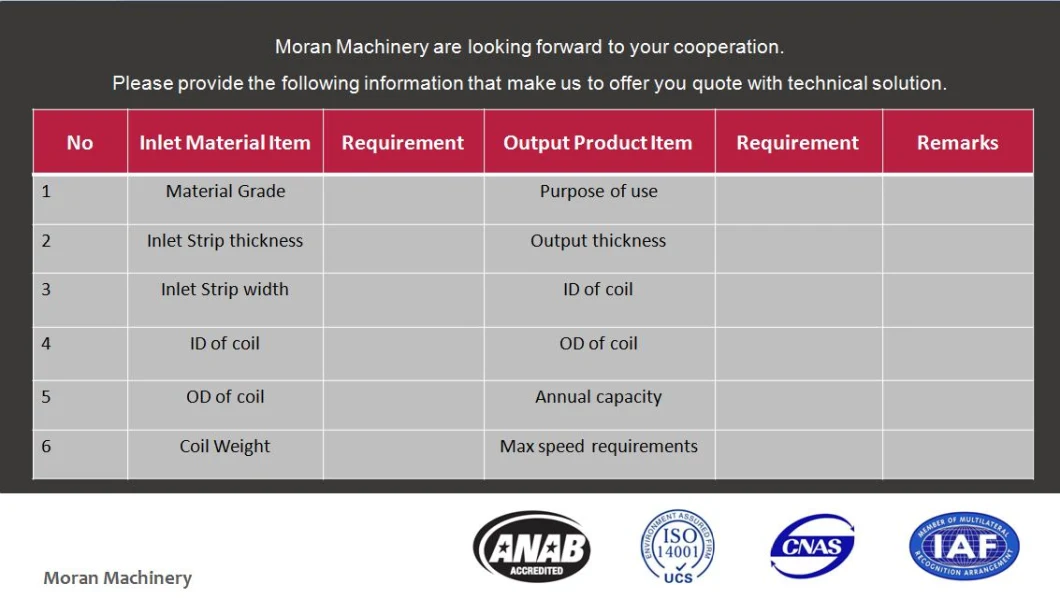

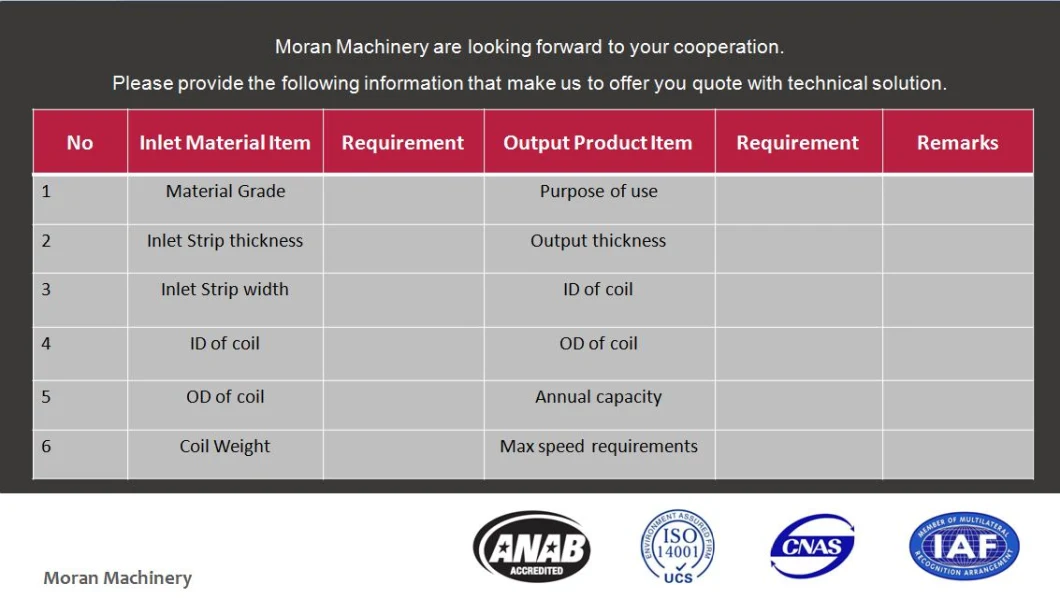

Moran Machinery are looking forward to your cooperation.

Liu Huan (Tony Liu)

Our website: Moranchina.en.made-in-china.com

Moran Machinery are looking forward to your cooperation.

Liu Huan (Tony Liu)

Our website: Moranchina.en.made-in-china.com