Basic Info.

Model NO.

Leadworld-001S

Product Name

Canned Food Production Line

Packaging

Tin, Glass

Automatic Grade

It Can Be Customized According to The Output

Dimension(L*W*H)

Customized

Usage

Plastic, Tin, Glass

Power Supply

3pH 380V 50/60Hz

Application

a Variety of Canned Fruits and Vegetables

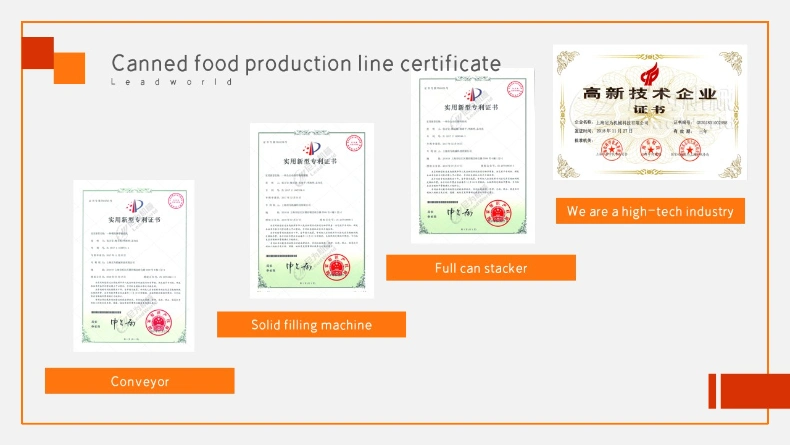

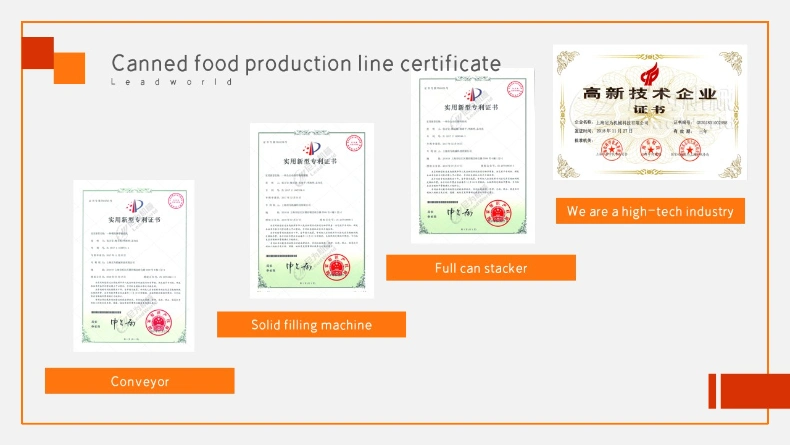

Certificate

CE SGS Ios

Feature

Easy to Clean

Material

Stainless Steel

Advantage

The Operation Is Simple

Transport Package

Wooden Case

Specification

customized

Trademark

lw

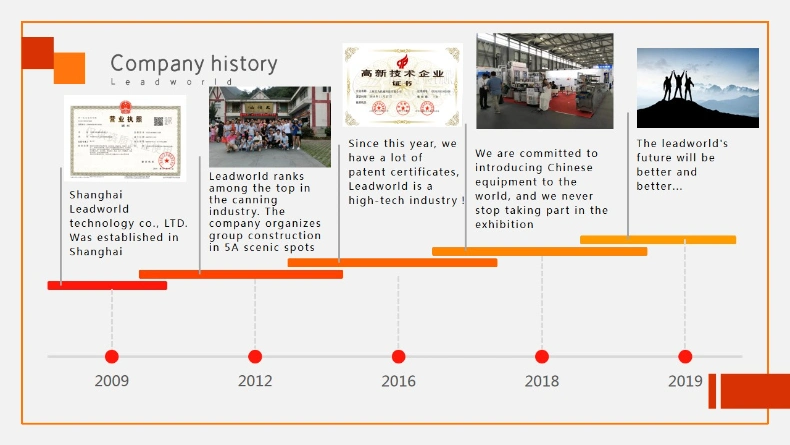

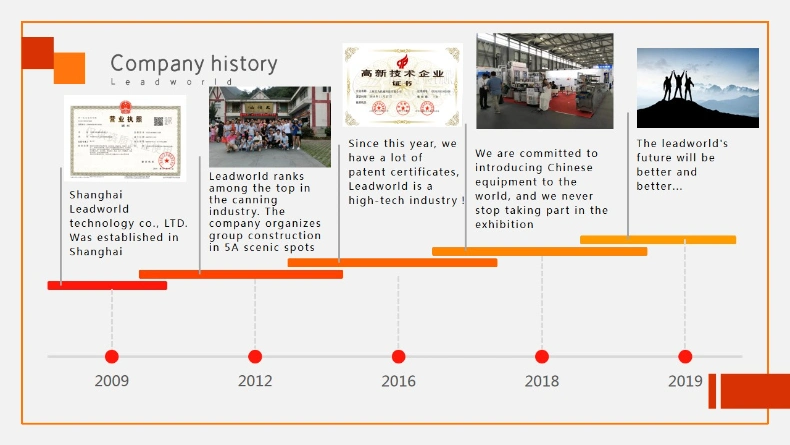

Origin

Shanghai

HS Code

190709000

Production Capacity

10 Set/Year

Product Description

Product Description

Automatic packaging machine for finished prefabricated vegetables packaging machine for fast food quick frozen food production line

1. It is controlled by PLC and equipped with touch screen man-machine interface control system, which is easy to operate

2. The bag storage device can store more bags, has low requirements on the quality of bags, and has a high rate of bag separation and loading

3. The film releasing part is designed with sterilization tank, cleaning tank and ultraviolet sterilization lamp. Three cleaning processes ensure the cleanness of the roll film

4. It can automatically complete the functions of multi column automatic quantitative measurement, automatic filling, automatic bag making, easy tearing, sealing and cutting of products

5. Use frequency conversion speed regulation device, and the speed can be adjusted freely within the specified range

6. Be more independent, flexible, correct and compatible during operation

Production Show

Product Application

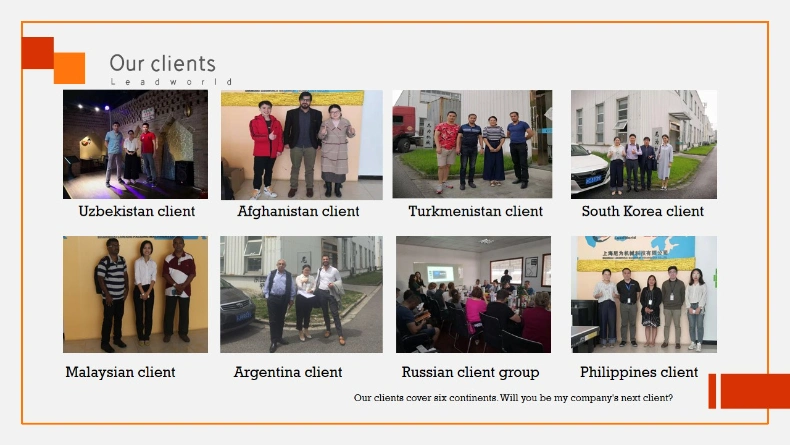

About us

About us

FAQ

Q1:Are you manufacturer or trading company?

We are manufacture verified by ALIBABA and we have our own design team.

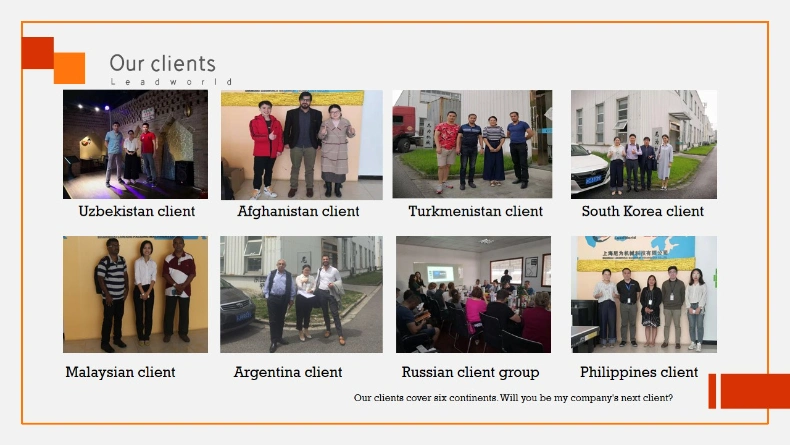

Q2:Where are you located? Is it convenient to visit you?

We are located in Shanghai. Traffic is very convenient.

Q3:How can you guarantee quality?

1.We have completed working system and procedures and we follow them very strictly.

2.Our different worker is responsible for different working process, their work is confirmed,and will always operate this process, so very experienced.

3.The electrical pneumatic components are from the world famous companies,such as Germany's Siemens, Japanese Panasonic etc.

4.We will do strict test running after the machine is finished.

5.Our machines are certified by CE,SGS,ISO.

Q4:Can you design the machine according to our requirements?

Yes. We not only can customize the machine according to your technical drawing, but also can design new machine according to your requirements.

Q5:Can you offer overseas technical support?

Yes. We can send engineer to your company to set the machine and train your worker if needed.

Automatic packaging machine for finished prefabricated vegetables packaging machine for fast food quick frozen food production line

1. It is controlled by PLC and equipped with touch screen man-machine interface control system, which is easy to operate

2. The bag storage device can store more bags, has low requirements on the quality of bags, and has a high rate of bag separation and loading

3. The film releasing part is designed with sterilization tank, cleaning tank and ultraviolet sterilization lamp. Three cleaning processes ensure the cleanness of the roll film

4. It can automatically complete the functions of multi column automatic quantitative measurement, automatic filling, automatic bag making, easy tearing, sealing and cutting of products

5. Use frequency conversion speed regulation device, and the speed can be adjusted freely within the specified range

6. Be more independent, flexible, correct and compatible during operation

Production Show

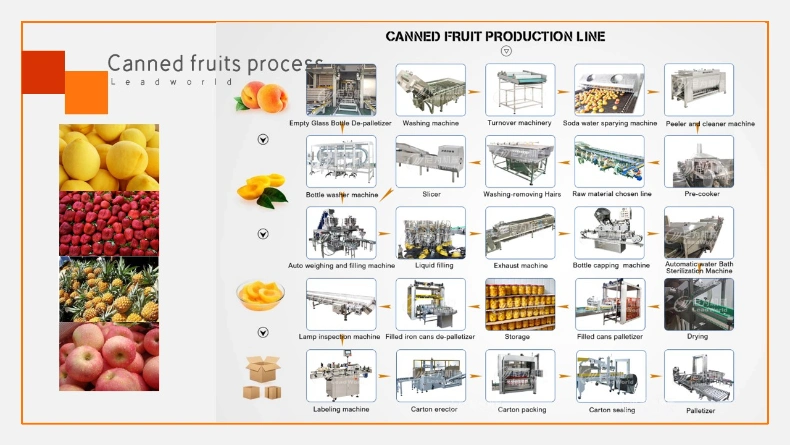

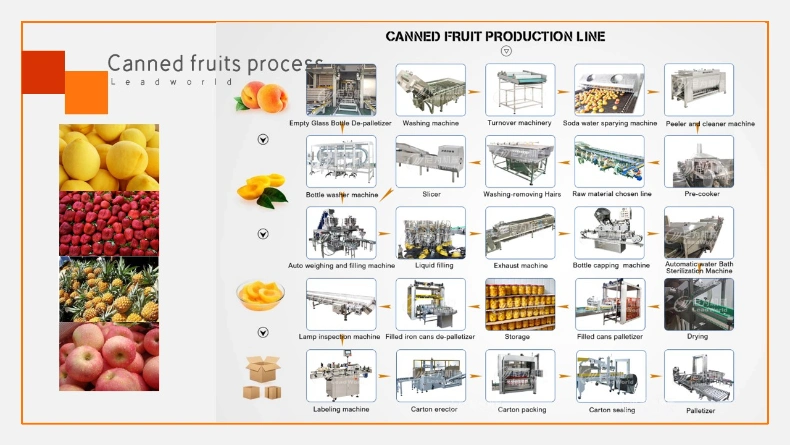

Item | Name | Model specifications |

1 | Washing Machine | Bubble(dry bean 1T/H) |

2 | Precooker | With cooling 5min (85ºC-90ºC) L=10m W=1100mm |

3 | Soak | With lifting |

4 | Washing machine | Bubble +lifting |

5 | Washing machine | Empty can |

6 | Lifting conveyor | moving to tank of filling machine |

7 | Filling Machine | use measuring working way |

8 | Filling Machine | liquid |

9 | Sealing Machine | Sealing Can(7113 can) |

10 | Loading Can | By magnetic |

11 | Unloading Can | By magnetic |

12 | Drying | By air |

13 | Labeling Machine | Sticker label |

14 | Print Machine | Print date(VIDEOJET) |

15 | Carton Erector | Automatic |

16 | Carton Sealing | Use tape |

Product Application

About us

About us

FAQ

Q1:Are you manufacturer or trading company?

We are manufacture verified by ALIBABA and we have our own design team.

Q2:Where are you located? Is it convenient to visit you?

We are located in Shanghai. Traffic is very convenient.

Q3:How can you guarantee quality?

1.We have completed working system and procedures and we follow them very strictly.

2.Our different worker is responsible for different working process, their work is confirmed,and will always operate this process, so very experienced.

3.The electrical pneumatic components are from the world famous companies,such as Germany's Siemens, Japanese Panasonic etc.

4.We will do strict test running after the machine is finished.

5.Our machines are certified by CE,SGS,ISO.

Q4:Can you design the machine according to our requirements?

Yes. We not only can customize the machine according to your technical drawing, but also can design new machine according to your requirements.

Q5:Can you offer overseas technical support?

Yes. We can send engineer to your company to set the machine and train your worker if needed.