- Overview

- Product Description

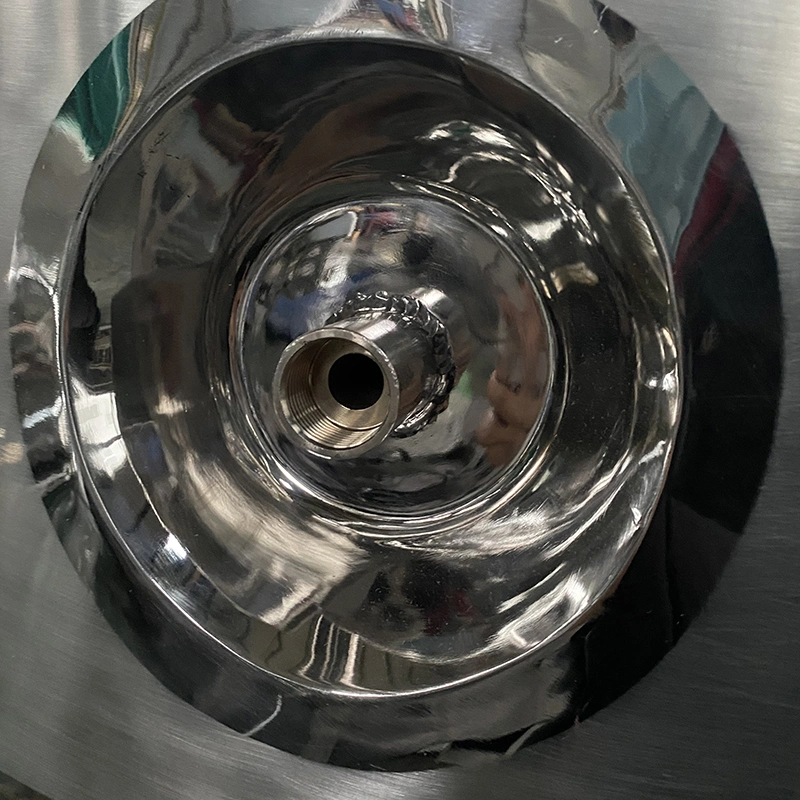

- Detailed Photos

- Product Parameters

- Packaging & Shipping

- Company Profile

- Our Products

- After Sales Service

- FAQ

Basic Info.

Packaging & Delivery

Product Description

Beverage Wine Liquor Fermentor Cider Yeast Fermentation Tank

Application:

The fermentation tank is a kind of equipment for mechanical stirring and fermentation of materials. The equipment adopts the internal circulation method and uses the stirring paddle to disperse and break the air bubbles. The tank body is made of SUS304 or SUS316L and the tank is equipped with automatic 360° CIP cleaning to make the production process meet the requirements of GMP. The inner surface of the tank is mirror polished to avoid hygienic dead angle. The fully enclosed design enables the materials to be mixed and fermented in a low-pollution and anoxic state. The equipment is equipped with air filter respirators, CIP cleaning nozzles, manholes. The tank body is equipped with interlayer and insulation layer which can be heated, cooled and kept warm. Fermentation tanks are used in dairy products, beverages, bioengineering, pharmaceuticals, fine chemicals.

The main components of the fermenter:

The tank body is mainly used to cultivate and ferment various bacteria with good sealing (to prevent the bacteria from being polluted)

Stirring paddles in the tank, which are used for continuous stirring during the fermentation process

The sparger in bottom ventilation is used to pass the air or oxygen needed for the growth of bacteria

There are control sensors on the top plate of the tank, the most commonly used ones are pH electrodes and DO electrodes which are used to monitor the pH and DO changes of the fermentation broth during the fermentation process. The controller is used to display and control fermentation conditions.

Instructions:

1) Calibrate the pH electrode and dissolved oxygen electrode.

2) Sterilize the tank. Put the culture medium into the tank as required, and seal it as required. Small-scale fermentation tanks (5L) can put the tank body into a large sterilizer for sterilization (115°C, 30 minutes); large-scale fermentation tanks (10L and above) Sterilize by steam (121°C, 30min).

3) After the tank is cooled, put it on the fermentation table and install it well; turn on the cooling water, turn on the power of the air pump, connect the ventilation pipe to start ventilation, adjust the intake knob to make the ventilation volume appropriate, and keep the tank pressure at 0.05MPa; Set the temperature, pH, stirring speed, etc., and calibrate the slope of the dissolved oxygen electrode at a certain speed and ventilation, and the value is 100%.

4) After the temperature is stable and all parameters are correct, insert the pre-shaken seeds, start the fermentation timing, and start recording various parameters.

5) After fermentation, clean the tank and electrodes, insert the pH electrode into the triangular flask with 3M potassium chloride for use, cover the probe of the dissolved oxygen electrode with a protective sleeve, and save it for later use.

| Model | Volume (L) | Tank size (mm) | Mixing speed (r/min) | Motor power (kw) |

| YFT-500 | 500 | ⊘700×1200 | 400 | 2.2 |

| YFT-1000 | 600 | ⊘900×1500 | 300 | 3 |

| YFT-1500 | 1500 | ⊘1100×1600 | 260 | 4 |

| YFT-2000 | 2000 | ⊘1200×1800 | 240 | 4 |

| YFT-3000 | 3000 | ⊘1200×2600 | 220 | 5.5 |

| YFT-5000 | 5000 | ⊘1400×3000 | 200 | 11 |

| YFT-10000 | 10000 | ⊘1800×3600 | 150 | 22 |

All of our products are packing by wooden case or paper box, delivery by air, ship or express.

All of our products are packing by wooden case or paper box, delivery by air, ship or express.

With 3800 square meters workhouse, we have kinds of processing machines such as lathes, laser cutter, metal rolling machine, polishing machine, spinning machine, pipe cutting machine, sheet bending machine, automatic puncher, automatic welding machine, CNC machine center and so on. Various processing is possible to complete the requirements of clients.

With 3800 square meters workhouse, we have kinds of processing machines such as lathes, laser cutter, metal rolling machine, polishing machine, spinning machine, pipe cutting machine, sheet bending machine, automatic puncher, automatic welding machine, CNC machine center and so on. Various processing is possible to complete the requirements of clients.

Our products list

Our products list

We provide a one-year warranty and consulting services.We can discuss in English on phone or online chating.

1. Are you real factory or trade company?

A: We are real factory locoal in Fujian, China. Welcome to visit our factory.

2.About the warranty.

A: Warranty is one year, our engineer will help you install and commission the machines.

3.Can you provide instant services?

A: Yes, we can discuss in English on phone or online chating.

4.Are you produce the standard machine or customizable models?

A: All of our products are customizable, please send us your requirement and other details.

5.What is the lead time?

A: According to the production, different size, different time.

6.Could you send the catalogues and technical documents?

A: Yes, please leave your email.

7.What about the after-sales?

A: We provide a one-year warranty and consulting services.