Basic Info.

Model NO.

DN50

Section Shape

Round

Length

Fixed or Random or Cutting

Quality Assurance

PMI Tested/Dimension/Visual

Thickness

Sch5s, Sch40,Sch80,Sch120,Sch160,Schxxs

Certificate

En10204 3.1 or 3.2 on Request

Transport Package

Bundles with Seaworthy

Specification

1/2"-24"

Trademark

KM/OEM

Origin

China

Production Capacity

1000 Ton/Year

Product Description

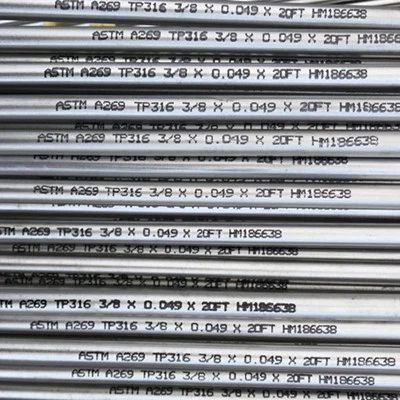

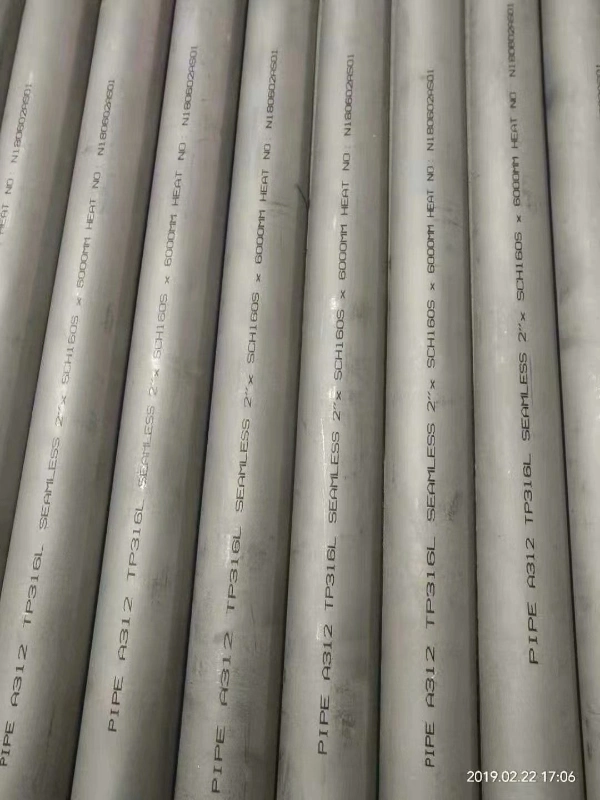

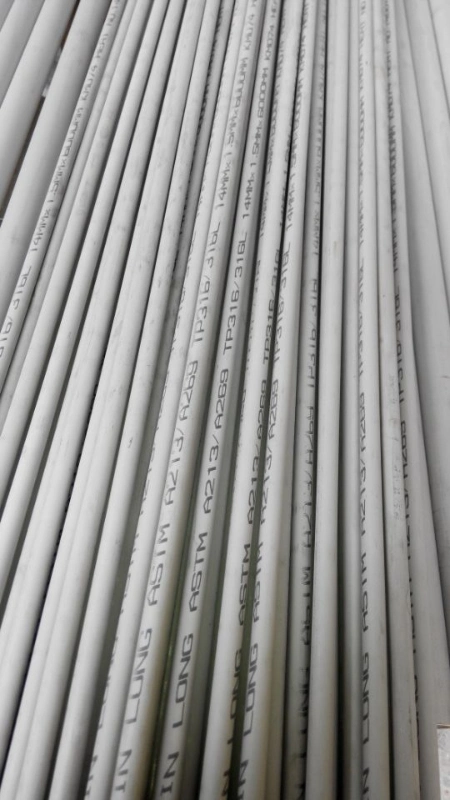

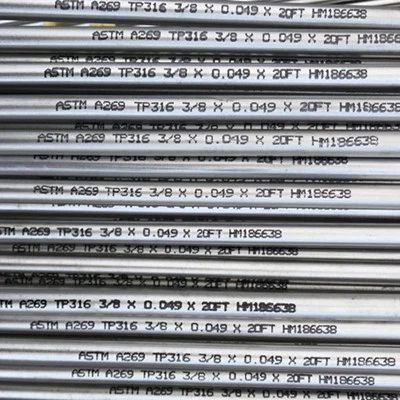

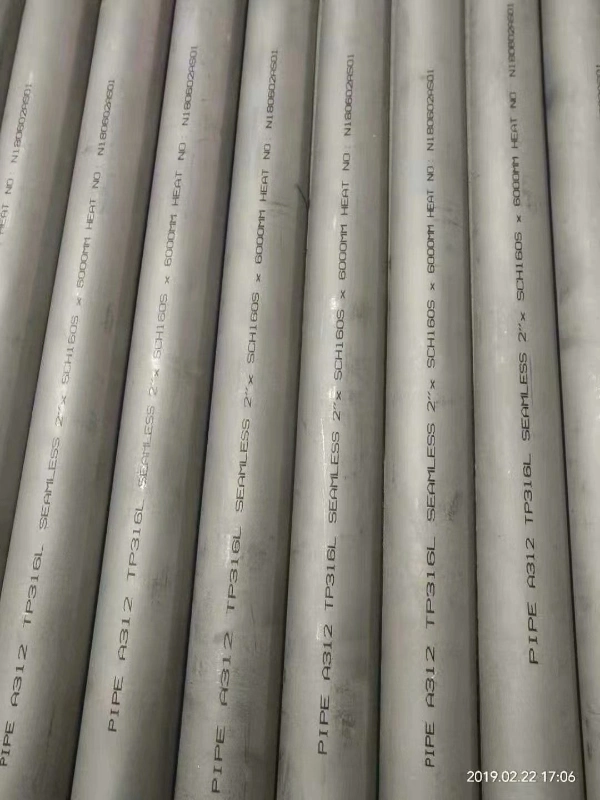

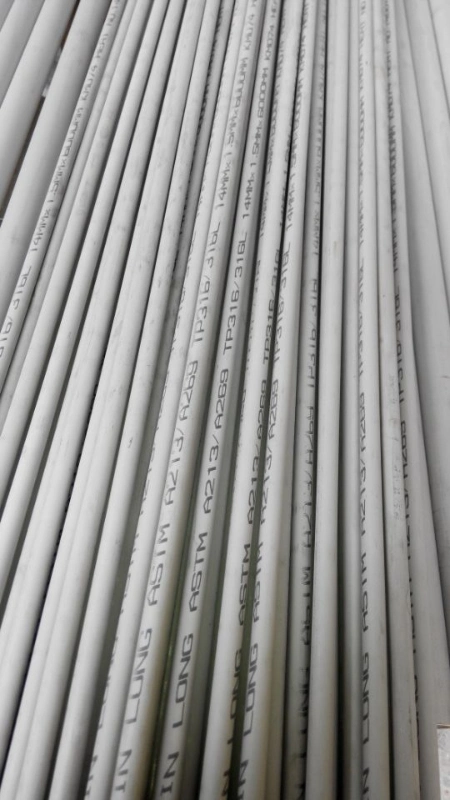

A312 A269 Tp316/316L Seamless Stainless Steel Pipe and Tube

ASTM A312 Grade TP316 and TP316L refer to the stainless steel 316 and 316L respectively. The prefix "TP" denotes "type" of the stainless steel. TP316 or TP316L pipes may be furnished in seamless or longitudinally welded types with butt welding ends or threaded ends. TP316 is derived from the classic "18-8" (TP304) stainless steel by adding molybdenum for enhanced pitting resistance in chloride environments. TP316L is the low carbon version of TP316, in which low carbon content improves sensitization for better welded corrosion resistance.

ASTM A312 TP316 and TP316L are designated with UNS S31600 and UNS S31603, respectively. Although more expensive, pipes made of TP316/ TP316L have higher level corrosion resistance than that of TP304/ TP304L. They can be used for a diversified range of corrosive chemical process piping which involves inks, rayon, photographic chemicals, paper, textiles, bleaches, and rubber.

*Based on product analysis.

*L: longitudinal elongation; *T: transverse elongation.

*t: nominal wall thickness; D: ordered outside diameter.

ASTM A312 TP316/ TP316L seamless pipes are generally furnished in sizes 1/2″ through 24″, while ASTM A312 TP316/ TP316L welded pipes are available from 1-1/2″ through 48″. The wall thicknesses shall be furnished in accordance with ASME B36.10M or ASME B36.19M. The pipes are usually supplied in lengths of 6.096 m (20′), 12.19 m (40′), 6 m, and 12 m, etc. No pipe shall be under the specified length and no pipe shall be more than 0.25″ [6 mm] over the specified length.

Company Profile

Company Profile

From 1989 to now, Kingmetal Steel focus on manufacturing and distributing pipeline products including piping, fitting, flange, valve and fastener in stainless, carbon, alloy and duplex steel.

Kingmetal has a factory to manufacture seamless stainless steel pipe from DN6 to DN600 and distribute seamless steel pipe and fitting from top brand manufacturers such as Baosteel, Hengsteel, Tiansteel and Pansteel etc.

All of products are strictly compliance with standard, 100% inspection passed including visual, dimension and PMI test before shipment.

Both our sales and logistic teams are over 10 years of experiences and training frequently.

After- sales service with high efficiency, if any products are short quantity/weight or damaged caused by manufacturing, design or transportation can be compensated.

Why choose us?

Why choose us?

One-Stop Solution

We have thousands of total production experience, from raw materials to finished products.

Competitive Price

Large scale purchase, standardized production process and efficient management make our price competitive.

Quick Shipping

Years of export experience enable us to control the transportation time more accurately.

Quality Control

The standardized production process, comprehensive management system, professional testing equipment

Special material customization

We support the customization of various complex materials

OEM/ODM

We support any form of OEM/ODM customization requirements.

ASTM A312 Grade TP316 and TP316L refer to the stainless steel 316 and 316L respectively. The prefix "TP" denotes "type" of the stainless steel. TP316 or TP316L pipes may be furnished in seamless or longitudinally welded types with butt welding ends or threaded ends. TP316 is derived from the classic "18-8" (TP304) stainless steel by adding molybdenum for enhanced pitting resistance in chloride environments. TP316L is the low carbon version of TP316, in which low carbon content improves sensitization for better welded corrosion resistance.

ASTM A312 TP316 and TP316L are designated with UNS S31600 and UNS S31603, respectively. Although more expensive, pipes made of TP316/ TP316L have higher level corrosion resistance than that of TP304/ TP304L. They can be used for a diversified range of corrosive chemical process piping which involves inks, rayon, photographic chemicals, paper, textiles, bleaches, and rubber.

Manufacture & Heat Treatment

Seamless pipes made of ASTM A312 TP316/ TP316L shall be made by a process that does not involve welding at any stage of production; welded pipes shall be manufactured using an automatic welding process with no addition of filler metal during the welding process. The TP316/ TP316L pipe shall be heat treated by solution treatment, in which the pipe shall be heated and held for long enough period at a temperature no less than 1900°F [1040°C] so that all chromium carbides can be fully austenitized or dissolved. Subsequent water cooling or rapid cooling by other means shall be conducted to ensure no precipitation of carbides at grain boundaries. Moreover, TP316L is less likely to precipitate chromium carbides compared to TP316 since their carbon content is low enough to reduce precipitation of intergranular carbides. This may result in limited sensitization hence benefit welding, flame cutting, and other hot-working operations.Chemical Composition Requirements

| Element | Composition, % TP316 | Composition, % TP316L |

| C | ≤0.08 | ≤0.035 |

| Mn | ≤2.00 | ≤2.00 |

| P | ≤0.045 | ≤0.045 |

| S | ≤0.030 | ≤0.030 |

| Si | ≤1.00 | ≤1.00 |

| Cr | 16.0-18.0 | 16.0-18.0 |

| Ni | 10.0-14.0 | 10.0-14.0 |

| Mo | 2.00-3.00 | 2.00-3.00 |

Mechanical Properties

| Tensile Requirements | TP316 | TP316L |

| Tensile Strength min. MPa [ksi] | 515 [75] | 485 [70] |

| Yield Strength min. MPa [ksi] | 205 [30] | 170 [25] |

| Elongation in 2", min, % (*L) | 35 | 35 |

| Elongation in 2", min, %(*T) | 25 | 25 |

Sizes, Dimensions & Tolerances

| NPS | *t/D | Tolerance, % from Nominal | |

| 1/8"~2.5" | All | +20.0 | -12.5 |

| 3"~18" | ≤5% | +22.5 | -12.5 |

| 3"~18" | >5% | +15.0 | -12.5 |

| ≥20" Wld. | All | +17.5 | -12.5 |

| ≥20" smls | ≤5% | +22.5 | -12.5 |

| ≥20" smls | >5% | +15.0 | -12.5 |

ASTM A312 TP316/ TP316L seamless pipes are generally furnished in sizes 1/2″ through 24″, while ASTM A312 TP316/ TP316L welded pipes are available from 1-1/2″ through 48″. The wall thicknesses shall be furnished in accordance with ASME B36.10M or ASME B36.19M. The pipes are usually supplied in lengths of 6.096 m (20′), 12.19 m (40′), 6 m, and 12 m, etc. No pipe shall be under the specified length and no pipe shall be more than 0.25″ [6 mm] over the specified length.

Inspection & Tests

Visual examination, dimensional inspection, PMI chemical analysis, tensile test, flattening test, bend test,eddy-current test, etching test,radiographic examination (for welded pipes), intergranular corrosion test (upon request).

Company Profile

Company Profile From 1989 to now, Kingmetal Steel focus on manufacturing and distributing pipeline products including piping, fitting, flange, valve and fastener in stainless, carbon, alloy and duplex steel.

Kingmetal has a factory to manufacture seamless stainless steel pipe from DN6 to DN600 and distribute seamless steel pipe and fitting from top brand manufacturers such as Baosteel, Hengsteel, Tiansteel and Pansteel etc.

All of products are strictly compliance with standard, 100% inspection passed including visual, dimension and PMI test before shipment.

Both our sales and logistic teams are over 10 years of experiences and training frequently.

After- sales service with high efficiency, if any products are short quantity/weight or damaged caused by manufacturing, design or transportation can be compensated.

Why choose us?

Why choose us? One-Stop Solution

We have thousands of total production experience, from raw materials to finished products.

Competitive Price

Large scale purchase, standardized production process and efficient management make our price competitive.

Quick Shipping

Years of export experience enable us to control the transportation time more accurately.

Quality Control

The standardized production process, comprehensive management system, professional testing equipment

Special material customization

We support the customization of various complex materials

OEM/ODM

We support any form of OEM/ODM customization requirements.